Gbólólólóhùn Asiri: Asiri rẹ ṣe pataki pupọ si wa. Ile-iṣẹ wa ṣe ileri lati ṣe sọ alaye ti ara ẹni si eyikeyi ifihan pẹlu awọn igbanilaaye rẹ.

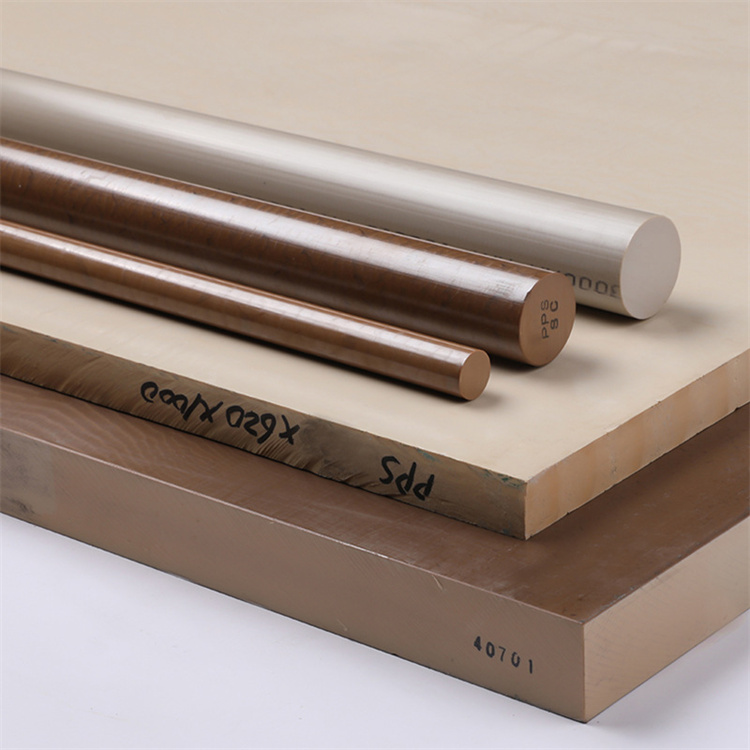

Engineering Plastic Pps Plate Sheet Rod Machined parts and

PPS injection molding is a white, highly crystalline, hard and brittle polymer. In addition, pps has the following performance characteristics, as follows:

1. General performance

① Very little water absorption

② Good flame retardancy

2. Warm blood performance

It can withstand 260 ℃ in the short term, and can be used for a long time at 200~240 ℃.

3. Mechanical properties

① High rigidity

② Good creep resistance

③ High wear resistance

④ High hardness

4. Environmental performance

① Radiation resistance

② Good chemical resistance

5. Electrical properties

① It has good arc resistance and is a commonly used electrical insulating material.

② Outstanding electrical performance.

In general, pps injection molding can be used in the automotive industry, household appliances, electronic appliances, machinery industry and other industries. Next, let's take a look at the matters needing attention before pps injection molding. It is recommended to pre-dry at 150-160°C for two to three hours or at 120°C for five hours, in order to enhance the appearance of the molded product. Especially for carbon fiber filled grades, pre-drying is very important because carbon fiber is very hygroscopic.

Let's talk about the molding process, as follows:

1. Injection molding

An injection molding machine can be used, and the melt index of glass fiber reinforced pps is 50.

2. Molding

It is suitable for large-scale productions, using two compressions, and then hot pressing after cooling.

3. Extrusion

A vented extruder can be used.

4. Spray molding

Using suspension spraying method and dry powder thermal spraying mixing method, pps is sprayed on the surface of the metal, and then plasticized, quenched and other treatments are used to obtain the coating

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

February 09, 2023

August 29, 2024

December 17, 2023

Imeeli si olupese yii

November 14, 2024

November 13, 2024

October 20, 2022

October 20, 2022

February 09, 2023

August 29, 2024

December 17, 2023

Gbólólólóhùn Asiri: Asiri rẹ ṣe pataki pupọ si wa. Ile-iṣẹ wa ṣe ileri lati ṣe sọ alaye ti ara ẹni si eyikeyi ifihan pẹlu awọn igbanilaaye rẹ.

Fọwọsi alaye diẹ sii ki o le wọle si ọ ni iyara

Gbólólólóhùn Asiri: Asiri rẹ ṣe pataki pupọ si wa. Ile-iṣẹ wa ṣe ileri lati ṣe sọ alaye ti ara ẹni si eyikeyi ifihan pẹlu awọn igbanilaaye rẹ.